FEP Lined Plug Valve Manufacturer, factory and supplier. FEP lined plug valve is the plug valve that have the internal part covered with FEP material. Due to the use of this FEP material the valve becomes very resistant to corrosion as well as being able to withstand high pressure and high temperature. This type of valve is in the category of quarter-turn valves. This is because FEP lined plug valve manufacturers design the valve such that it only needs a quarter turn of the handle to open or close the fluid flow. This valve is operated using a handle or by use of actuators such as hydraulic, pneumatic, and electric actuators. PTFE-lined plug valve manufacturers design this valve for on and off applications as well as throttling fluid flow. However, for throttling, this valve results in a lot of pressure drop and thus it should only be used if the piping system has very low-pressure drop.

Various types of FEP lined plug valve include 3 way FEP lined plug valve, pneumatic FEP lined plug valve and electric FEP lined plug valve among others. The areas of applications of PTFE lined plug valve include pharmaceuticals, foods and beverages, chemical processing, sewage treatment, water supply, and petrochemicals among others. The advantages of using this valve are resistance to corrosion, fast operation, low initial cost, low-pressure drop, low maintenance, easy installation, cleaning and repair, and zero leakage.

FEP lined plug valve manufacturer produces this plug valve to operate using a handwheel/hand lever or by using actuators. FEP lined plug valve is in the class of quarter turn valves. This means that the valve needs a quarter turn of the handle or actuator and then it will either start or stop depending on the direction of rotation. This characteristic makes this plug valve very fast and simple to operate. FEP lined plug valve can be used in various applications such as foods, oil and gas, water supply, and chemical processing among others.

FEP Lined plug valve specification:

Size Range : DN15 to DN600, NPS 1/2 to NPS 24

Class Range : PN10 PN16,150LB

Design Standard : API6D / API599 or Others

Face To Face Standard: ASME B16.10 or Others

Flange End Standard:ASME B 16.5 or Others

Body Material: WCB, ASTM A395 , CF8 ,CF8M

Lining Material: PTFE , PFA , PO ,FEP

End Connection : Double Flanged RF

Operation : Lever / Handwheel / Pneumatic / Electrical

Temperature Range : -40°C to +180°C

Pressure Testing : API 598 / API 6D / EN 12266-1/ISO 5208

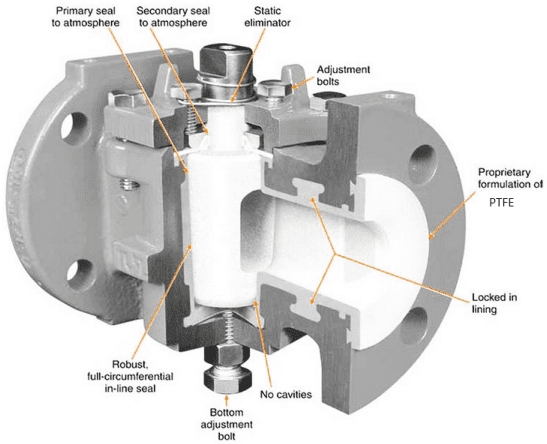

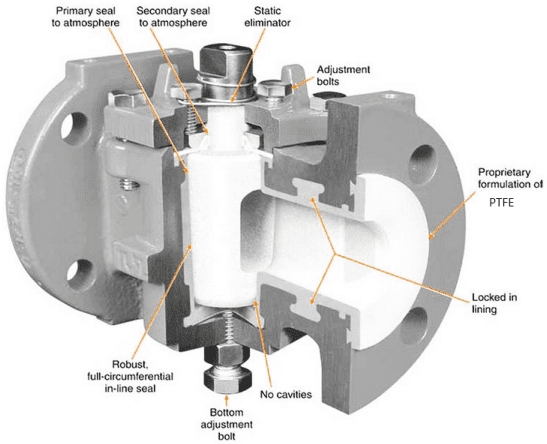

FEP lined plug valve component:

Handle

The handle in a FEP lined plug valve is the part where one applies torque to open or close fluid flow. The handle is used in manually operated valves. For an automatic valve, an actuator is used. The actuator is tasked with providing the torque that the valve needs to open or close the fluid flow.

Stem

This is the component that transmits the torque applied on the handle by the operator to the plug. FEP lined plug valve manufacturer design the stem with threads that help the stem to rotate.

Plug

The plug is the component that helps to open or close the fluid flow. It gets the power to operate from the valve stem. It is connected to the stem through its top end. The plug has a port or more than one port which when aligned with the valve ports allows fluid to flow through the valve.

Valve body

The valve body is used to house internal parts of the FEP lined plug valve such as the plug and seat. This component is usually made of very strong metallic materials such as carbon steel and stainless steel among others. This ensures the valve body remains very strong against high pressure as well as impact damage. The valve body also contains the inlet and exit ports of the valve that are connected to the pipeline.

Body cover

The body cover is placed on top of the valve body and as the name suggests, it helps to cover the body’s top part to prevent any fluid leakage. It is through the body cover that the valve can be opened for inspection and cleaning while it is still connected to the pipe. The body cover and valve body are made of the same metallic material.

Gaskets

These components are used to prevent fluid leakage between the body cover and the valve body as well as between the pipe and the valve body connection. Bolts and nuts as well as screw threads are used to tighten the connection where the gasket is mounted.

FEP lined plug valve Application

1. FEP lined plug valve is used in chemical processing plants.

2. They are used in the manufacturing of fertilizers.

3. FEP lined plug valves is used in food and beverage processing plants.

4. They are used in water supply and waste water treatment.

5. They are used in pharmaceutical manufacturing plants.

6. FEP lined plug valve is used in fluid diversion and mixing.

7. They are used in petrochemical industries.